Meta Description: A manual 8-hole zero-point master plate with 52×52 and 96×96 locating patterns helps shops swap vises and chucks fast, reduce interference, and keep repeatability high.

SEO Keywords: 8-hole zero-point master plate, manual quick-change, 52×52 locating holes, 96×96 locating holes, D52 pull stud, D96 pull stud

Mixed Fixtures Are Normal Now—Your Base Strategy Should Match

Modern CNC scheduling rarely stays clean. You might run a small aluminum batch, then a larger workpiece that needs a different vise, then a round part that’s best in a chuck. When every fixture swap requires re-indicating and re-validating, setup time becomes the bottleneck.

The fix isn’t owning more fixtures. It’s building a base platform that makes fixture swaps predictable.

What the 8-Hole Manual Quick-Change System Is

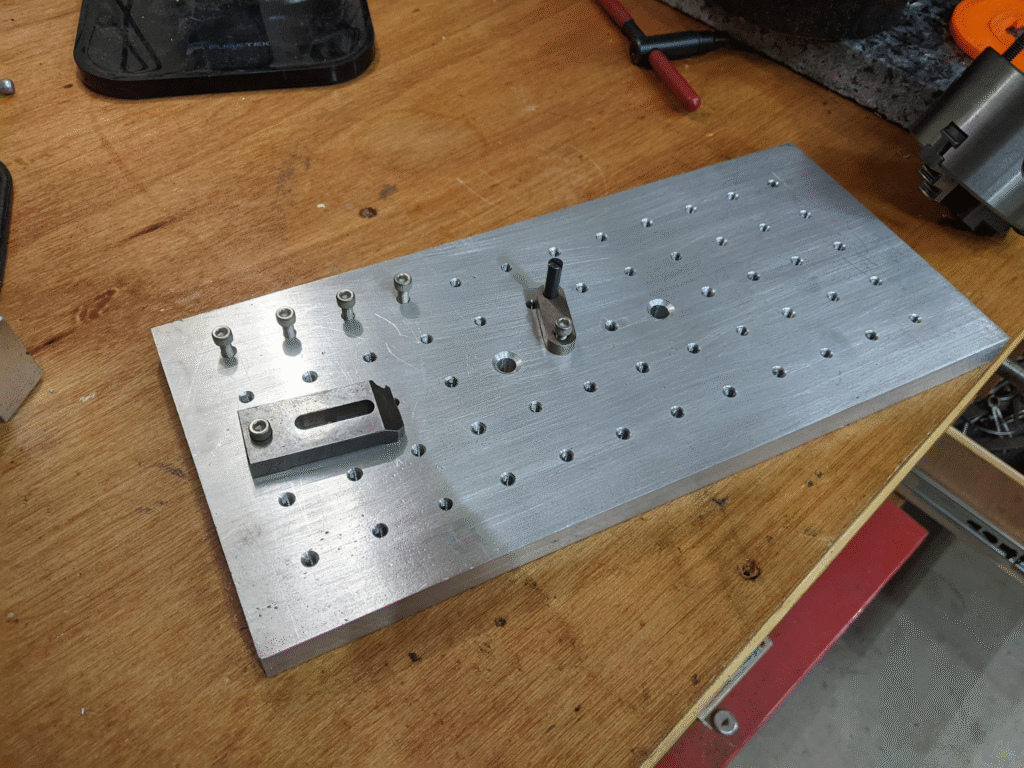

Xindian describes an 8-hole zero-point quick-change system as a manually clamped master plate designed for rapid locking and high-precision positioning. It features 52×52mm and 96×96mm locating holes, compatible with D52 pull studs and D96 pull studs respectively.

This dual-pattern platform matters because it lets one machine table support multiple fixture “classes” without changing the base.

The Real Advantage: Switch Fixtures to Reduce Interference

One of the most practical lines in the product description is about why this matters during real machining: the system enables quick switching between hydraulic vise, D96 vises, and various-sized three-jaw chucks when machining different workpiece sizes. The stated outcome is reduced machining interference and improved efficiency across diverse materials and dimensions.

This directly impacts cycle planning:

- Better clearance means fewer tool compromises.

- Fewer compromises means shorter tools, less chatter risk, and simpler toolpaths.

- Simpler toolpaths mean smoother production when jobs change.

Key Specs That Turn It Into a “Foundation Plate”

The listing includes several performance claims that define how the system is intended to be used:

- Up to 90% less set-up time

- Bearing capacity: 200 kg

- High repetition accuracy: 0.005mm

- Positioning and clamping in one operation

Even if your real-world setup savings vary, these specs tell you the plate is designed as a serious base layer, not a lightweight accessory.

A Practical Workflow That Works in Real Shops

Here’s how many shops get the best result from a master-plate platform:

1) Mount the master plate and treat it as “permanent”

Qualify it once. After that, avoid removing it unless you need maintenance.

2) Standardize fixture plates

Put your most common 5th axis vise and fixtures on dedicated plates so they’re ready to dock. The whole point is to stop rebuilding setups.

3) Use the right locating pattern intentionally

Use 52×52 for compact fixtures and 96×96 for larger ones—then label them clearly so operators don’t guess.

4) Choose fixtures for access, not habit

When a job is tight on clearance, switching to a different fixture type (vise vs chuck, small vs large) becomes easy—so you can optimize for tool access and interference reduction.

Where This Pays Off Fastest

This platform approach is most valuable when:

- you run high-mix / low-to-mid volume,

- you get frequent rush jobs and schedule interrupts,

- you’re trying to reduce operator-to-operator variability,

- you want repeat jobs to restart without “setup amnesia.”

The core value is not just speed—it’s recoverability: the ability to pause a setup and return to it later without rebuilding everything.

Maintenance Mindset: Simple System, Serious Discipline

Manual quick-change systems don’t require pneumatics, but they still require discipline:

- keep interfaces clean,

- protect locating features from dings,

- keep pull stud practice consistent,

- store plates safely and labeled.

Repeatability is a system outcome, not a single component outcome.

Bottom Line

A dual-pattern master plate is a clean answer to mixed-fixture reality. Xindian’s 8-hole system is described as manual clamping with 52×52 and 96×96 locating holes, the ability to switch between vises/chucks to reduce interference, 0.005mm repetition accuracy, 200kg bearing capacity, and “positioning + clamping in one operation.”

CTA: If changeovers are killing your schedule, standardize your base first. Once the base is stable, fixture swapping becomes a tool—not a penalty.